Rotomolding Mixers

Rotomolding Mixers

Rotomolding High Intensity Mixing requires less energy than PVC, Color Concentrates, Toners, and other Applications but needs enough to give a homogeneous mix in a short time frame. The typical tip speed of the mixing tools will be 20 meters per second. Typically at this speed, Polyethylene and Pigments get mixed within 3-5 minutes.

Reliance Rotomolding High Intensity Mixers (RFM) come in our Standard design. Our High Intensity Mixers are designed with efficiency and user friendliness in mind. The Assemblies and Components are engineered to maximize production and minimize down time associated with a plant’s maintenance program.

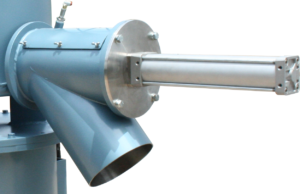

Rotomolding High Intensity Mixer Discharge: Reliance High Intensity Mixer Discharge openings are designed for fast and efficient removal of material from the Mixer Bowl. The discharge assembly is supplied with a In addition, the assemblies can be supplied with easy clean features that facilitate fast turn-arounds.

Rotomolding High Intensity Mixer Lid: Reliance High Intensity Mixer Lids are flanged dished ends that are machined flat and supplied with a dome shaped gasket. The gasket supplies a leak proof seal with the top ring of the mixer bowl. Reliance High Intensity Mixer Lids are constructed out of Stainless Steel and can be mirror polished for easy cleaning. They can come in a Clam-Shell, Swivel, or Pivot / Tilt Design. Lid openings are made to customers requirement.

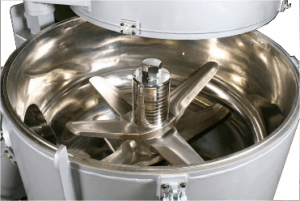

Rotomolding High Intensity Mixer Tools: Reliance High Intensity Mixer Tools are specially designed to fluidize material and create a deep vortex flow pattern within the Mixer Bowl. They are self-cleaning and polished smooth. Uniquely engineered tools can be provided to suit your mixing and application needs.

Rotomolding High Intensity Mixer Deflector: Reliance High Intensity Mixer Deflectors are designed to turn the material into the vortex of the mixer. By forcing the material back into the center of the bowl, a highly homogenized end product can be achieved. They are not required in the mixing of Polyethylene but can be added as an option.

English

English Español

Español